/ Designing for Convenience, Control, and Safety

In the electric power steering system, a compact brushless DC (BLDC) motor is attached to the steering column and works with several sensors to detect the amount of torque being applied by the driver.

Maintaining constant communication and feedback based on the driver’s speed, torque, and other sensor data, the EPS increases or decreases power to help the driver steer based on real-time driving conditions. At lower speeds, the steering wheel can be turned easily, and at higher speeds, it requires a bit more resistance to give the driver a feeling of control.

Brushless DC (BLDC) motors are relatively compact and cost-effective, delivering long-lasting operation, easy installation, and reduced EMI noise to enhance EPS performance.

/ Application Considerations

When designing electric power steering systems, engineers must account for a variety of demanding performance parameters to ensure flawless operation under any driving conditions. The following considerations are critical for creating a system that is not only efficient and responsive but also robust enough to handle the rigors of daily use. Here are some key factors to keep in mind:

- High-temperature capability - components must withstand the worst-case scenario in thermal surges caused by torque assistant pulses.

- High current handling - the system should perform reliably under the worst possible conditions and current surges.

- Low on-resistance - minimizing heat generated during operation extends the life of the component, and low RDS(on) plays a crucial role while enhancing system responsiveness.

- EMI protection - proper suppression and filtration are needed to reduce noise and electromagnetic interference.

- Fast switching speed - switching should be fast enough to ensure smooth operation amid ever-changing conditions.

- Low reverse recovery time - low Trr is needed to enable faster switching at high frequencies and improve efficiency.

- Applicable industry standards - to ensure maximum safety and reliability, adherence to AEC-Q101 and other standards is required for certain components.

/ Enable Reliable Electric Power Steering

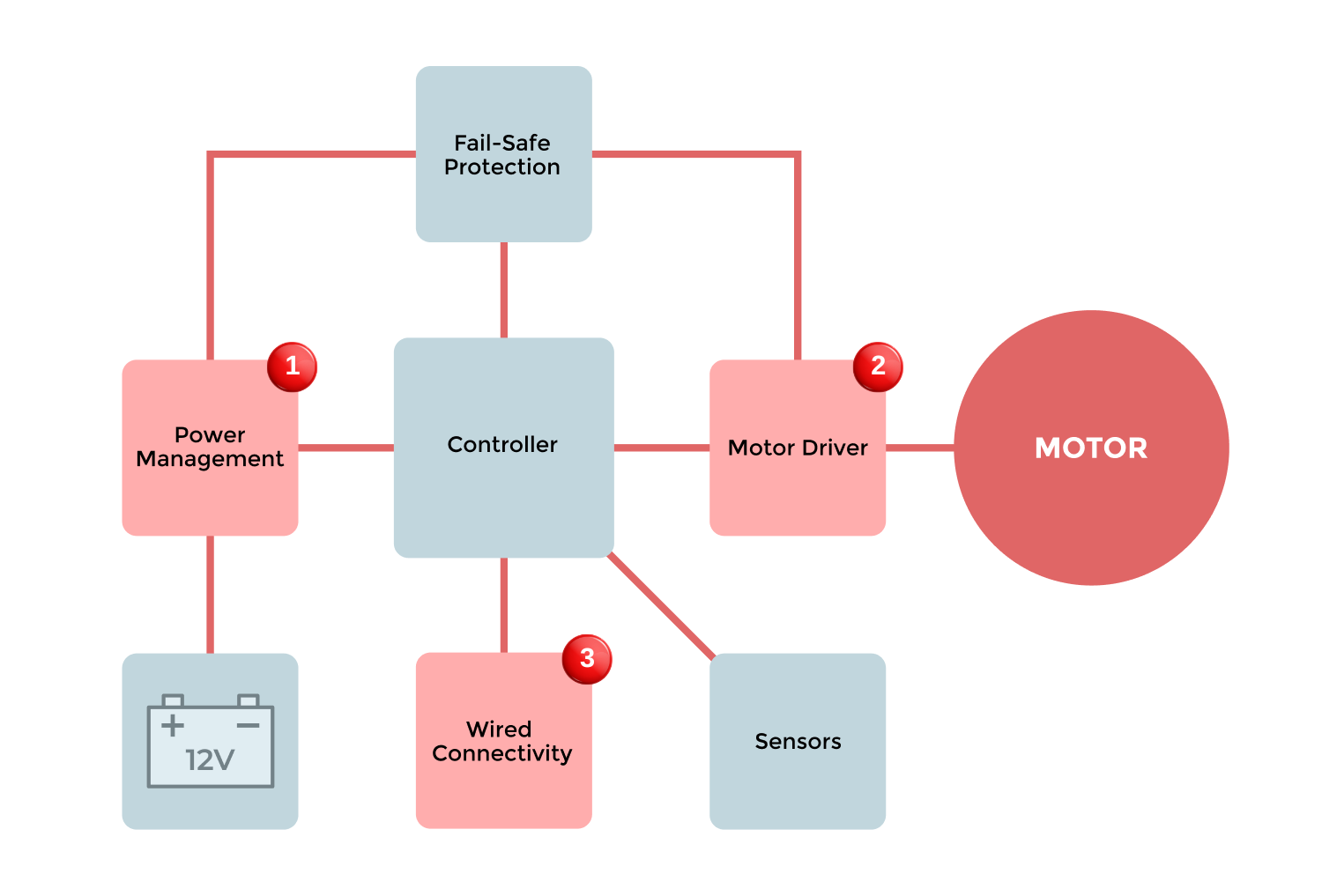

/ Block Diagram

/Recommended Products

Get a Competitive Edge on Your Next Project

No matter the application or industry, MCC has the components and service you need to get to market faster and reduce overall costs.

EXPLORE AUTO APPLICATIONS